UR Pulleys?

#3

read...

The Danger of Power Pulleys &

Understanding the Harmonic Damper

BY STEVE DINAN OF DINAN BMW

I have been threatening for a long time to write a series of technical articles to educate consumers and to dispel misconceptions that exist about automotive after-market technology. Motivated by problems with customer's cars resulting from the installation of power pulleys, I wish to explain the potential dangers of these products and address the damage they cause to engines.

The theory behind the power pulley is that a reduction in the speed of the accessory drive will minimize the parasitic losses that rob power from the engine. Parasitic power losses are a result of the energy that the engine uses to turn accessory components such as the alternator and water pump, instead of producing power for acceleration. In an attempt to minimize this energy loss, many companies claim to produce additional power by removing the harmonic damper and replacing it with a lightweight assembly. While a small power gain can be realized, there are a significant number of potential problems associated with this modification, some that are small and one which is particularly large and damaging!

The popular method for making power pulleys on E36 engines is by removing the harmonic damper and replacing it with a lightweight alloy assembly. This is a very dangerous product because this damper is essential to the longevity of an engine. The substitution of this part often results in severe engine damage.

It is also important to understand that while the engine in a BMW is designed by a team of qualified engineers, these power pulleys are created and installed by people who do not understand some very important principles of physics. I would first like to give a brief explanation of these principles which are critical to the proper operation of an engine.

1) Elastic Deformation

Though it is common belief that large steel parts such as crankshafts are rigid and inflexible, this is not true. When a force acts on a crank it bends, flexes and twists just as a rubber band would. While this movement is often very small, it can have a significant impact on how an engine functions.

2) Natural Frequency

All objects have a natural frequency that they resonate (vibrate) at when struck with a hammer. An everyday example of this is a tuning fork. The sound that a particular fork makes is directly related to the frequency that it is vibrating at. This is its "natural frequency," that is dictated by the size, shape and material of the instrument. Just like a tuning fork, a crankshaft has a natural frequency that it vibrates at when struck. An important aspect of this principle is that when an object is exposed to a heavily amplified order of its own natural frequency, it will begin to resonate with increasing vigor until it vibrates itself to pieces (fatigue failure).

3) Fatigue Failure

Fatigue failure is when a material, metal in this case, breaks from repeated twisting or bending. A paper clip makes a great example. Take a paper clip and flex it back and forth 90° or so. After about 10 oscillations the paper clip will break of fatigue failure.

The explanation of the destructive nature of power pulleys begins with the two basic balance and vibration modes in an internal combustion engine. It is of great importance that these modes are understood as being separate and distinct.

1) The vibration of the engine and its rigid components caused by the imbalance of the rotating and reciprocating parts. This is why we have counterweights on the crankshaft to offset the mass of the piston and rod as well as the reason for balancing the components in the engine.

2) The vibration of the engine components due to their individual elastic deformations. These deformations are a result of the periodic combustion impulses that create torsional forces on the crankshaft and camshaft. These torques excite the shafts into sequential orders of vibration, and lateral oscillation. Engine vibration of this sort is counteracted by the harmonic damper and is the primary subject of this paper.

Torsional Vibration (Natural Frequency)

Every time a cylinder fires, the force twists the crankshaft. When the cylinder stops firing the force ceases to act and the crankshaft starts to return to the untwisted position. However, the crankshaft will overshoot and begin to twist in the opposite direction, and then back again. Though this back-and-forth twisting motion decays over a number of repetitions due to internal friction, the frequency of vibration remains unique to the particular crankshaft.

Our motto at Dinan is "Performance without sacrifice" We feel our customers expect ultra high performance along with the legendary comfort and reliability of a standard BMW.

While it is common that a Dinan BMW is the fastest BMW you can buy, performance is not our only goal. Dinan isn't just trying to make the fastest car. Instead a host of considerations go into the development of our products. Dinan puts much more effort into these other areas than does our competition.

These considerations are Performance, Reliability (Warranty), Driveability, Emissions, Value, Fit and Finish. We feel that the power pulley is a bad way to get extra power from and engine and the potential for serious engine damage is too great.

This is a simplified explanation meant to be comprehensible by those who are not automotive engineers. In trying to simplify an extremely complex topic some precision was sacrificed although we believe this explanation to be as accurate as possible. We encourage our customers to educate themselves and understand the automotive after-market because we believe that our products are the best researched, engineered, and fabricated products available.

For those interested in a more in depth and technical explanation of this topic, the reference book is Advanced Engine Technology, written by Heinz Heisler MSc,BSc,FIMI,MIRTE,MCIT. Heinz Heisler is the Head of Transportation Studies at The College of North West London. His book is distributed in this country by the SAE (Society of Automotive Engineers).

The Danger of Power Pulleys &

Understanding the Harmonic Damper

BY STEVE DINAN OF DINAN BMW

I have been threatening for a long time to write a series of technical articles to educate consumers and to dispel misconceptions that exist about automotive after-market technology. Motivated by problems with customer's cars resulting from the installation of power pulleys, I wish to explain the potential dangers of these products and address the damage they cause to engines.

The theory behind the power pulley is that a reduction in the speed of the accessory drive will minimize the parasitic losses that rob power from the engine. Parasitic power losses are a result of the energy that the engine uses to turn accessory components such as the alternator and water pump, instead of producing power for acceleration. In an attempt to minimize this energy loss, many companies claim to produce additional power by removing the harmonic damper and replacing it with a lightweight assembly. While a small power gain can be realized, there are a significant number of potential problems associated with this modification, some that are small and one which is particularly large and damaging!

The popular method for making power pulleys on E36 engines is by removing the harmonic damper and replacing it with a lightweight alloy assembly. This is a very dangerous product because this damper is essential to the longevity of an engine. The substitution of this part often results in severe engine damage.

It is also important to understand that while the engine in a BMW is designed by a team of qualified engineers, these power pulleys are created and installed by people who do not understand some very important principles of physics. I would first like to give a brief explanation of these principles which are critical to the proper operation of an engine.

1) Elastic Deformation

Though it is common belief that large steel parts such as crankshafts are rigid and inflexible, this is not true. When a force acts on a crank it bends, flexes and twists just as a rubber band would. While this movement is often very small, it can have a significant impact on how an engine functions.

2) Natural Frequency

All objects have a natural frequency that they resonate (vibrate) at when struck with a hammer. An everyday example of this is a tuning fork. The sound that a particular fork makes is directly related to the frequency that it is vibrating at. This is its "natural frequency," that is dictated by the size, shape and material of the instrument. Just like a tuning fork, a crankshaft has a natural frequency that it vibrates at when struck. An important aspect of this principle is that when an object is exposed to a heavily amplified order of its own natural frequency, it will begin to resonate with increasing vigor until it vibrates itself to pieces (fatigue failure).

3) Fatigue Failure

Fatigue failure is when a material, metal in this case, breaks from repeated twisting or bending. A paper clip makes a great example. Take a paper clip and flex it back and forth 90° or so. After about 10 oscillations the paper clip will break of fatigue failure.

The explanation of the destructive nature of power pulleys begins with the two basic balance and vibration modes in an internal combustion engine. It is of great importance that these modes are understood as being separate and distinct.

1) The vibration of the engine and its rigid components caused by the imbalance of the rotating and reciprocating parts. This is why we have counterweights on the crankshaft to offset the mass of the piston and rod as well as the reason for balancing the components in the engine.

2) The vibration of the engine components due to their individual elastic deformations. These deformations are a result of the periodic combustion impulses that create torsional forces on the crankshaft and camshaft. These torques excite the shafts into sequential orders of vibration, and lateral oscillation. Engine vibration of this sort is counteracted by the harmonic damper and is the primary subject of this paper.

Torsional Vibration (Natural Frequency)

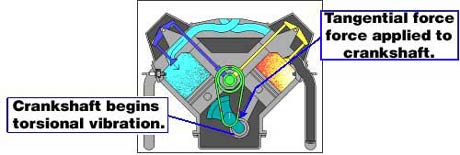

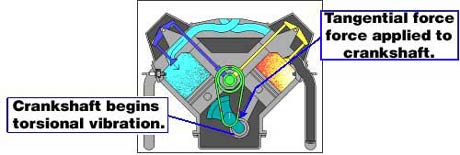

Every time a cylinder fires, the force twists the crankshaft. When the cylinder stops firing the force ceases to act and the crankshaft starts to return to the untwisted position. However, the crankshaft will overshoot and begin to twist in the opposite direction, and then back again. Though this back-and-forth twisting motion decays over a number of repetitions due to internal friction, the frequency of vibration remains unique to the particular crankshaft.

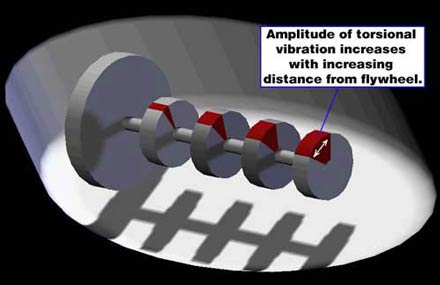

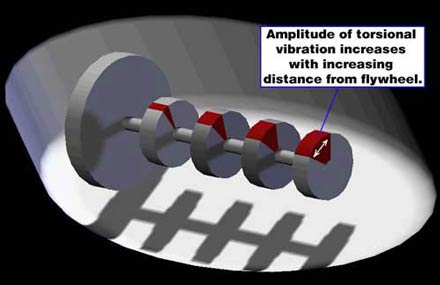

This motion is complicated in the case of a crankshaft because the amplitude of the vibration varies along the shaft. The crankshaft will experience torsional vibrations of the greatest amplitude at the point furthest from the flywheel or load.

Harmonic (sine wave) Torque Curves

Each time a cylinder fires, force is translated through the piston and the connecting rod to the crankshaft pin. This force is then applied tangentially to, and causes the rotation of the crankshaft.

The sequence of forces that the crankshaft is subjected to is commonly organized into variable tangential torque curves that in turn can be resolved into either a constant mean torque curve or an infinite number of sine wave torque curves. These curves, known as harmonics, follow orders that depend on the number of complete vibrations (cylinder pulses) per revolution. Accordingly, the tangential crankshaft torque is comprised of many harmonics of varying amplitudes and frequencies. This is where the name "harmonic damper" originates.

Each time a cylinder fires, force is translated through the piston and the connecting rod to the crankshaft pin. This force is then applied tangentially to, and causes the rotation of the crankshaft.

The sequence of forces that the crankshaft is subjected to is commonly organized into variable tangential torque curves that in turn can be resolved into either a constant mean torque curve or an infinite number of sine wave torque curves. These curves, known as harmonics, follow orders that depend on the number of complete vibrations (cylinder pulses) per revolution. Accordingly, the tangential crankshaft torque is comprised of many harmonics of varying amplitudes and frequencies. This is where the name "harmonic damper" originates.

Critical RPM's

When the crankshaft is revolving at an RPM such that the torque frequency, or one of the harmonic sine wave frequencies coincides with the natural frequency of the shaft, resonance occurs. Thus, the crankshaft RPM at which this resonance occurs is known a critical speed. A modern automobile engine will commonly pass through multiple critical speeds over the range of its possible RPM's. These speeds are categorized into either major or minor critical RPM's.

Major and Minor Critical RPM’s

Major and minor critical RPM's are different due to the fact that some harmonics assist one another in producing large vibrations, whereas other harmonics cancel each other out. Hence, the important critical RPM’s have harmonics that build on one another to amplify the torsional motion of the crankshaft. These critical RPM’s are know as the "major criticals". Conversely, the "minor criticals" exist at RPM's that tend to cancel and damp the oscillations of the crankshaft.

If the RPM remains at or near one of the major criticals for any length of time, fatigue failure of the crankshaft is probable. Major critical RPM’s are dangerous, and either must be avoided or properly damped. Additionally, smaller but still serious problems can result from an undamped crankshaft. The oscillation of the crankshaft at a major critical speed will commonly sheer the front crank pulley and the flywheel from the crankshaft. I have witnessed front pulley hub keys being sheered, flywheels coming loose, and clutch covers coming apart. These failures have often required crankshaft and/or gearbox replacement.

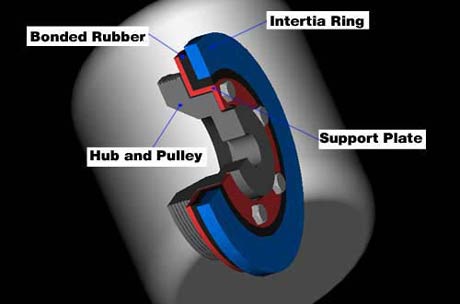

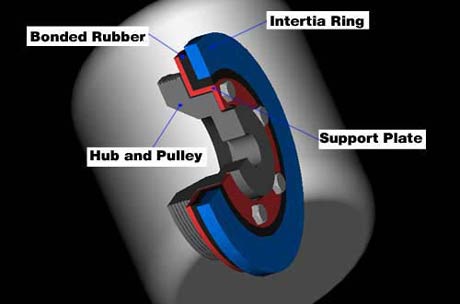

Harmonic Dampers

Crankshaft failure can be prevented by mounting some form of vibration damper at the front end of the crankshaft that is capable of absorbing and dissipating the majority of the vibratory energy. Once absorbed by the damper the energy is released in the form of heat, making adequate cooling a necessity. This heat dissipation was visibly essential in Tom Milner's PTG racing M3 which channeled air from the brake ducts to the harmonic damper, in order to keep the damper at optimal operating temperatures. While there are various types of torsional vibration dampers, BMW engines are primarily designed with "tuned rubber" dampers.

When the crankshaft is revolving at an RPM such that the torque frequency, or one of the harmonic sine wave frequencies coincides with the natural frequency of the shaft, resonance occurs. Thus, the crankshaft RPM at which this resonance occurs is known a critical speed. A modern automobile engine will commonly pass through multiple critical speeds over the range of its possible RPM's. These speeds are categorized into either major or minor critical RPM's.

Major and Minor Critical RPM’s

Major and minor critical RPM's are different due to the fact that some harmonics assist one another in producing large vibrations, whereas other harmonics cancel each other out. Hence, the important critical RPM’s have harmonics that build on one another to amplify the torsional motion of the crankshaft. These critical RPM’s are know as the "major criticals". Conversely, the "minor criticals" exist at RPM's that tend to cancel and damp the oscillations of the crankshaft.

If the RPM remains at or near one of the major criticals for any length of time, fatigue failure of the crankshaft is probable. Major critical RPM’s are dangerous, and either must be avoided or properly damped. Additionally, smaller but still serious problems can result from an undamped crankshaft. The oscillation of the crankshaft at a major critical speed will commonly sheer the front crank pulley and the flywheel from the crankshaft. I have witnessed front pulley hub keys being sheered, flywheels coming loose, and clutch covers coming apart. These failures have often required crankshaft and/or gearbox replacement.

Harmonic Dampers

Crankshaft failure can be prevented by mounting some form of vibration damper at the front end of the crankshaft that is capable of absorbing and dissipating the majority of the vibratory energy. Once absorbed by the damper the energy is released in the form of heat, making adequate cooling a necessity. This heat dissipation was visibly essential in Tom Milner's PTG racing M3 which channeled air from the brake ducts to the harmonic damper, in order to keep the damper at optimal operating temperatures. While there are various types of torsional vibration dampers, BMW engines are primarily designed with "tuned rubber" dampers.

It is also important to note that while the large springs of a dual mass flywheel absorb some of the torsional impulses conveyed to the crankshaft, they are not harmonic dampers, and are only responsible for a small reduction in vibration.

In addition to the crankshaft issue, other problems can result from slowing down the accessories below their designed speeds, particularly at idle. Slowing the alternator down can result in reduced charging of the battery, dimming of the lights, and computer malfunctions. Slowing of the water pump and fan can result in warm running, while slowing of the power steering can cause stiff steering at idle and groaning noises. It is possible to implement design corrections and avoid these scenarios, but this would require additional components and/or software.Our motto at Dinan is "Performance without sacrifice" We feel our customers expect ultra high performance along with the legendary comfort and reliability of a standard BMW.

While it is common that a Dinan BMW is the fastest BMW you can buy, performance is not our only goal. Dinan isn't just trying to make the fastest car. Instead a host of considerations go into the development of our products. Dinan puts much more effort into these other areas than does our competition.

These considerations are Performance, Reliability (Warranty), Driveability, Emissions, Value, Fit and Finish. We feel that the power pulley is a bad way to get extra power from and engine and the potential for serious engine damage is too great.

This is a simplified explanation meant to be comprehensible by those who are not automotive engineers. In trying to simplify an extremely complex topic some precision was sacrificed although we believe this explanation to be as accurate as possible. We encourage our customers to educate themselves and understand the automotive after-market because we believe that our products are the best researched, engineered, and fabricated products available.

For those interested in a more in depth and technical explanation of this topic, the reference book is Advanced Engine Technology, written by Heinz Heisler MSc,BSc,FIMI,MIRTE,MCIT. Heinz Heisler is the Head of Transportation Studies at The College of North West London. His book is distributed in this country by the SAE (Society of Automotive Engineers).

#4

so the factory pulleys are designed specifically for the engine, and putting in aftermarket ones will just throw off the balance of a lot of components. Thanks for that article, helped me make my decision. Pulleys aren't worth it

#5

Have you ever seen an engine that had been damaged solely by the addition of an underdrive pulley? Do you have a way to determine if the damage was caused by a pulley and not abuse or lack of oil? I'm not trying to be a butt, but a lot of people say they damage motors and quote others about the subject without any first hand experience. I have 2 cars in my driveway right now using UR pulley's for 20K plus miles with absolutely no issues. 1 is a D16Z6(stock bottom end) that regularly saw 8600 rpm shifts at the strip and had either a 75 or 100 shot on it. The motor is out now for a swap but ran flawlessly despite the abuse and over 100K mileage. I ran a UR race pulley on that motor from ~70k till it came out. The other pulley is on my beater Integra(100K+ miles), never had an issue with it either. I ran a UR pulley on my 98 ITR that was raced weekly for 3 years and shifted at 9200, again, no issues.

I have been racing Honda's since 93 and every motor I raced had a UR pulley on it. Most main and rod bearing failures in Honda motors are from abuse or lack of oil pressure. I'm not saying that you or the person quoted in your sticky are wrong or right, I'm speaking solely from personal experience. So you understand where I'm coming from: I have been a tech since the mid 90's, had a performance shop for years that specialized in Honda's and high end european builds, I have 4 years with BMW(certified tech), 2 years with Land Rover(shop foreman with master level training) and numerous yrs as a tech at independent shops. I don't know everything and don't pretend to, I only speak from first hand experience.

BTW, almost all the E36 and E46 M3's that I worked on and were raced had underdrive pulleys on them too, again, no ill effects.

I'm not flaming you or saying anything bad(I understand that you are a moderator), I just take issue with your conclusion about pulley's

I have been racing Honda's since 93 and every motor I raced had a UR pulley on it. Most main and rod bearing failures in Honda motors are from abuse or lack of oil pressure. I'm not saying that you or the person quoted in your sticky are wrong or right, I'm speaking solely from personal experience. So you understand where I'm coming from: I have been a tech since the mid 90's, had a performance shop for years that specialized in Honda's and high end european builds, I have 4 years with BMW(certified tech), 2 years with Land Rover(shop foreman with master level training) and numerous yrs as a tech at independent shops. I don't know everything and don't pretend to, I only speak from first hand experience.

BTW, almost all the E36 and E46 M3's that I worked on and were raced had underdrive pulleys on them too, again, no ill effects.

I'm not flaming you or saying anything bad(I understand that you are a moderator), I just take issue with your conclusion about pulley's

Last edited by g22cd5; 09-21-2010 at 07:55 PM. Reason: watch your mouth

#6

Iv seen many many h series and b series engines damaged by the overpriced pulleys. Everyone is diff. and ppl are gonna put w/e part on their car anyways no matter what you tell them. The pulleys for the price are worthless...you are hardly feeing up any rotating mass...if you want to do something along thos lines delete your power steering and a/c free up WAY more rotating mass the a overpriced pulley that WILL eat your main bearings up.

I’m sorry but physics don’t lie. Everyone has their opinion but I'm sticking to facts/physics

I’m sorry but physics don’t lie. Everyone has their opinion but I'm sticking to facts/physics

Last edited by g22cd5; 09-21-2010 at 07:58 PM.

#7

Everyone is entitled to their opinion, I guess we have just had different experiences. I always get rid of ac and ps in anything I'm gonna spin fast, I also use light flywheels to free things up a bit. On my old CRX motor I got almost 15lbs of rotating mass out with a race pulley(under a pound) and super light aluminum flywheel(6.5Lbs). It revved like it was possessed but was tough to get a stable idle below 1K rpm. Idle problems are the only thing I've ever had issues with when removing alot of rotating mass.

Thread

Thread Starter

Forum

Replies

Last Post